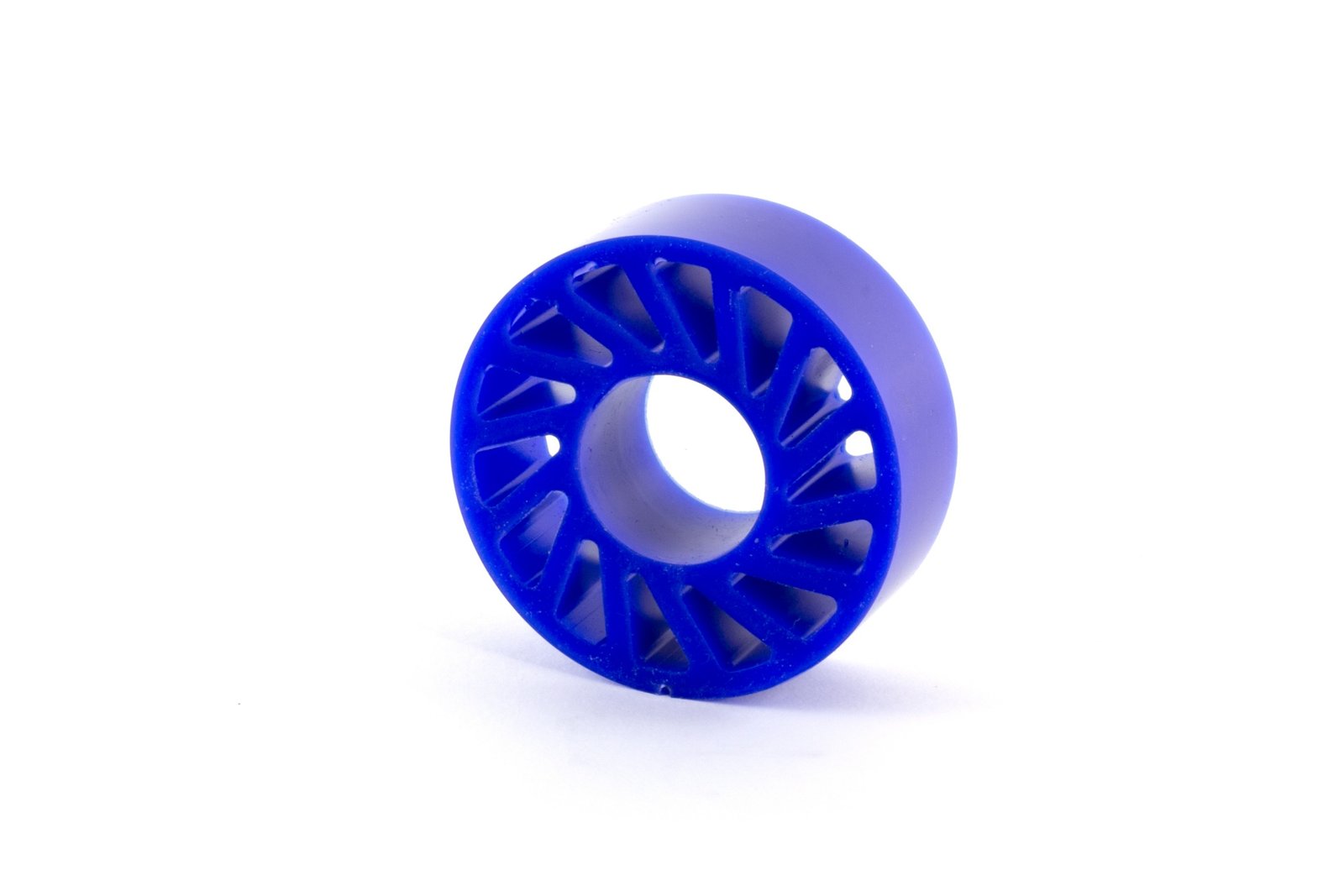

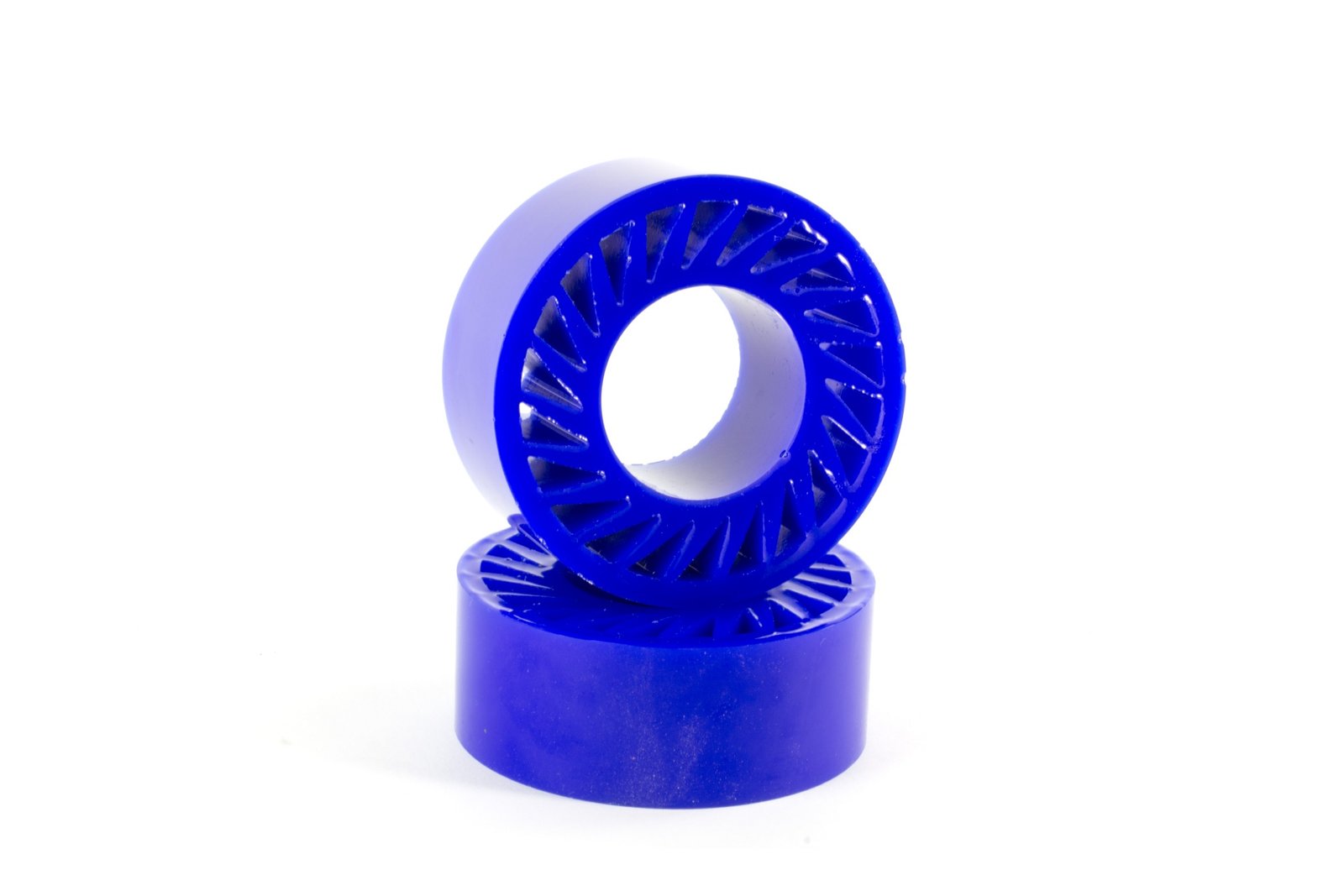

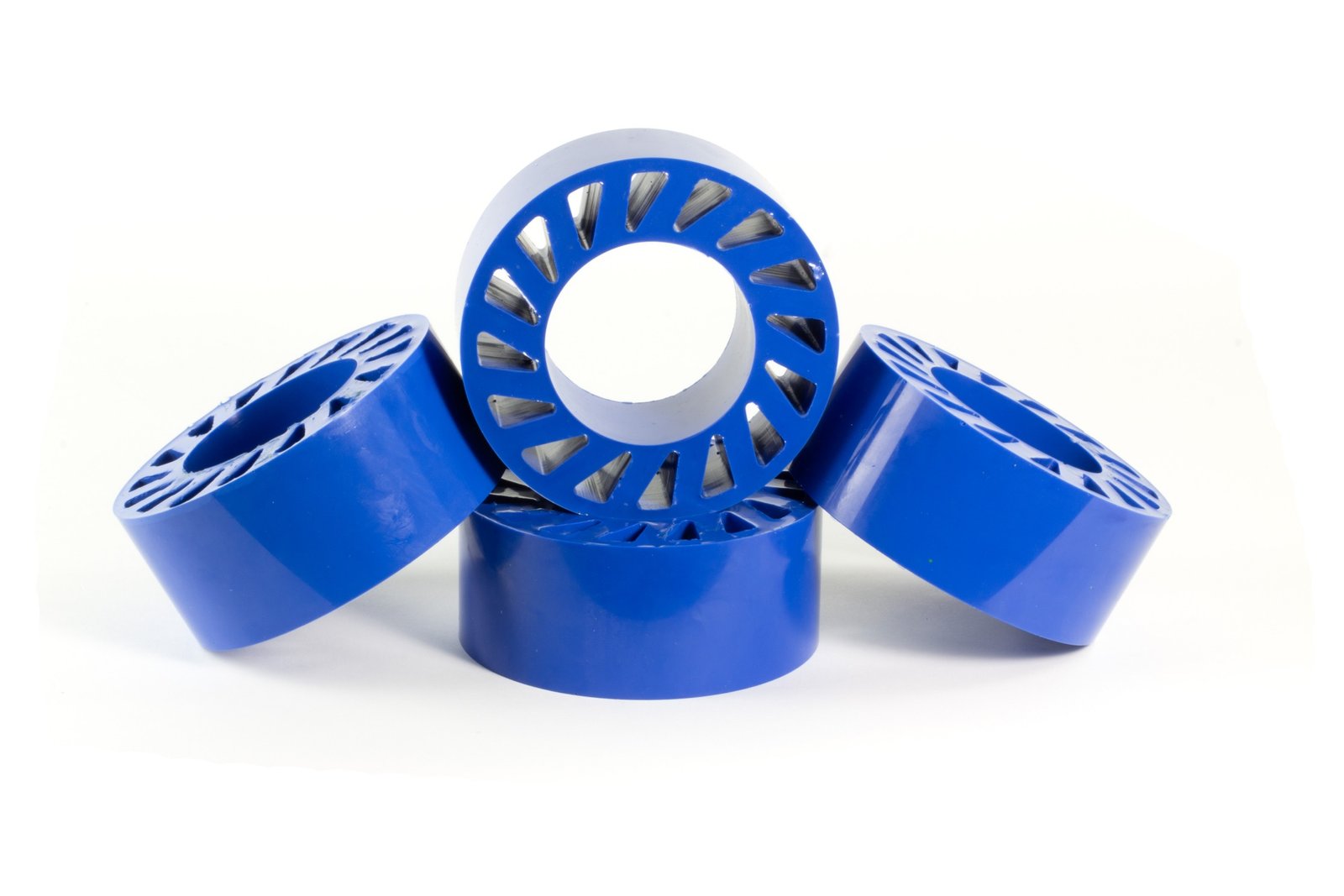

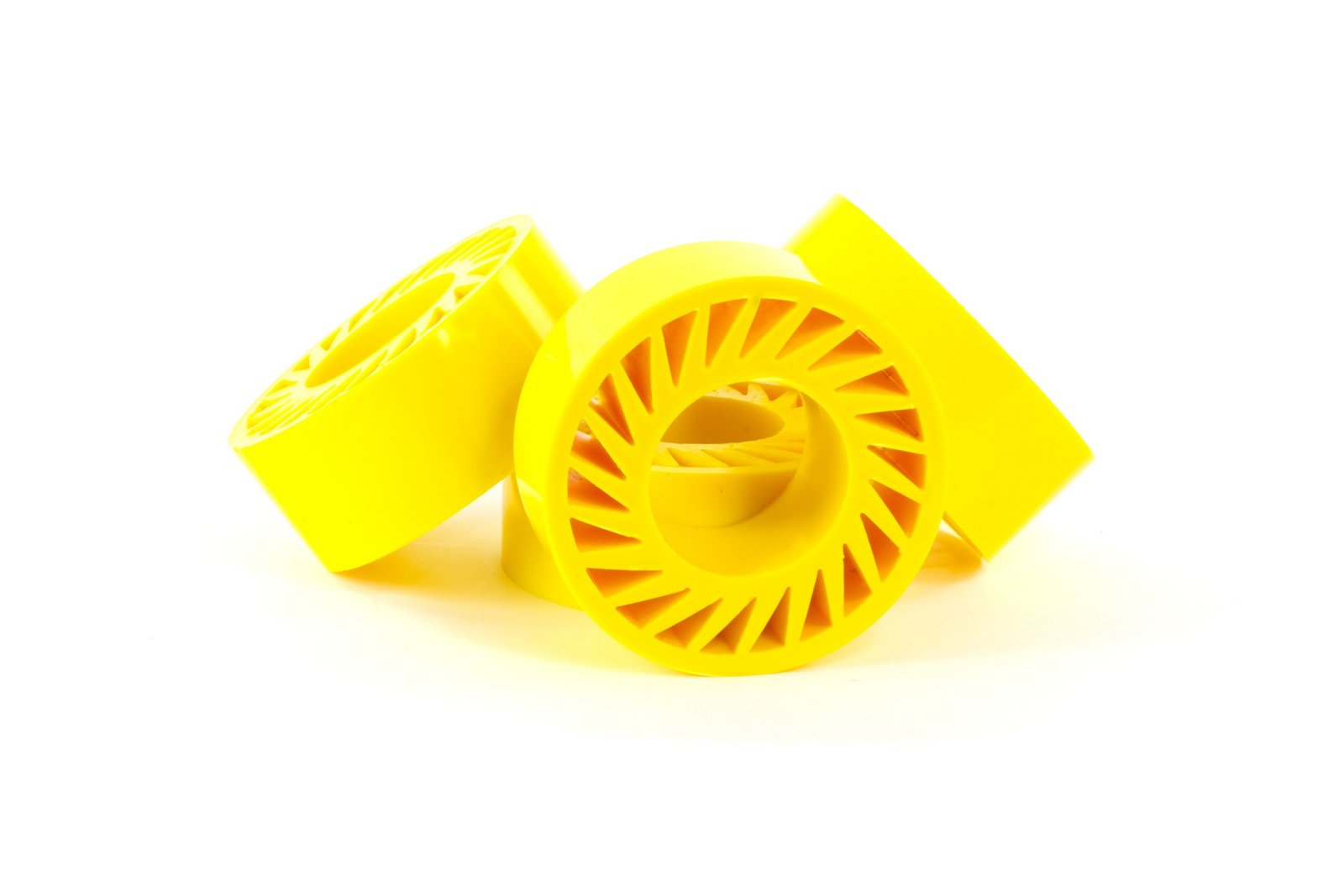

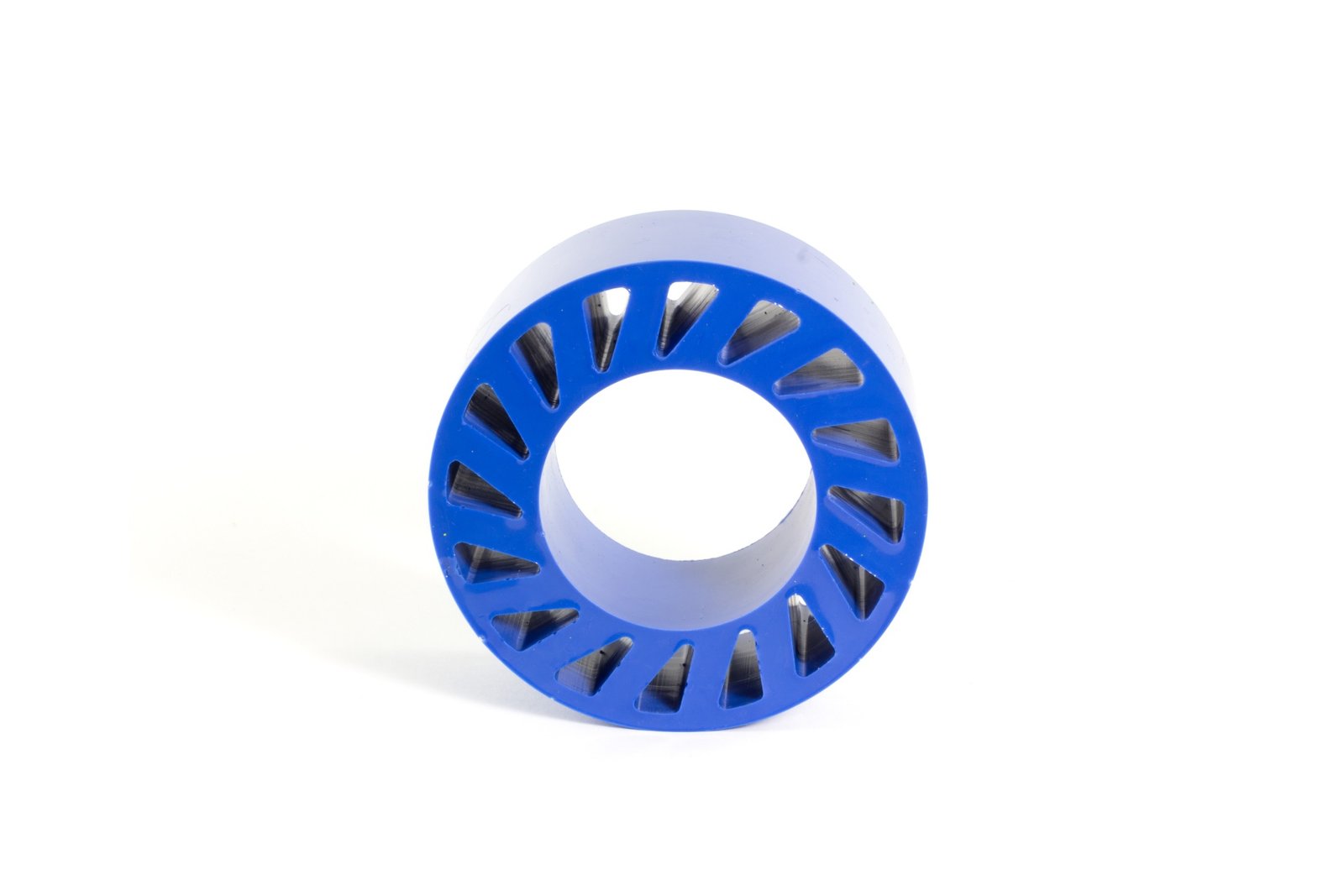

Slip-on No-Crush Wheels

Slip-on, Polyurethane-Only No-Crush Wheels

NoCrushWheels.com specializes in Slip-on No-Crush Wheels—high-performance, polyurethane-only no-crush wheels engineered to deliver reliability, flexibility, and fast integration for your applications. Designed to slip directly onto a shaft or press into an existing hub, our wheels are an alternative to traditional No-Crush Wheels that are bonded to a core, making them ideal for OEMs, design engineers, and mechanical system integrators.

Whether you need a cost-effective prototype, a rapid replacement, or a custom solution to integrate into your machinery, our Coreless No-Crush Wheels are tailored to your specs with fast lead times and unmatched versatility.

Why Choose Coreless No-Crush Wheels?

Slip-on No-Crush Wheels are molded entirely from durable ML6 polyurethane and designed to slip-fit or press-fit onto a shaft or core. With no metal or plastic hub, you benefit from:

- Reduced cost – No core = lower total component price

- Faster lead times – No time spent machining or sourcing hubs

- Simplified installation – Just slip it on or press-fit as needed

- Flexible replacements – Drop-in option for existing systems

These advantages make Coreless No-Crush Wheels ideal for packaging machines, conveyor systems, label applicators, and any application where performance, consistency, and durability are critical.

Fully Customizable to Your Application

Applications Across Industries

Our Slip-on No-Crush Wheels are trusted by leading OEMs, design engineers, and mechanical system integrators across a variety of industries:

- Packaging & Printing

- Food Processing Equipment

- Bottling & Labeling Systems

- Paper & Tissue Converting

- Automated Material Handling

Our Slip-On No-Crush Wheel design ensures low wear, excellent reliability, and performance under compression—all without the cost or complexity of molding to a core.