5.0″ No-Crush Drive Wheels

$65.00 – $68.00Price range: $65.00 through $68.00

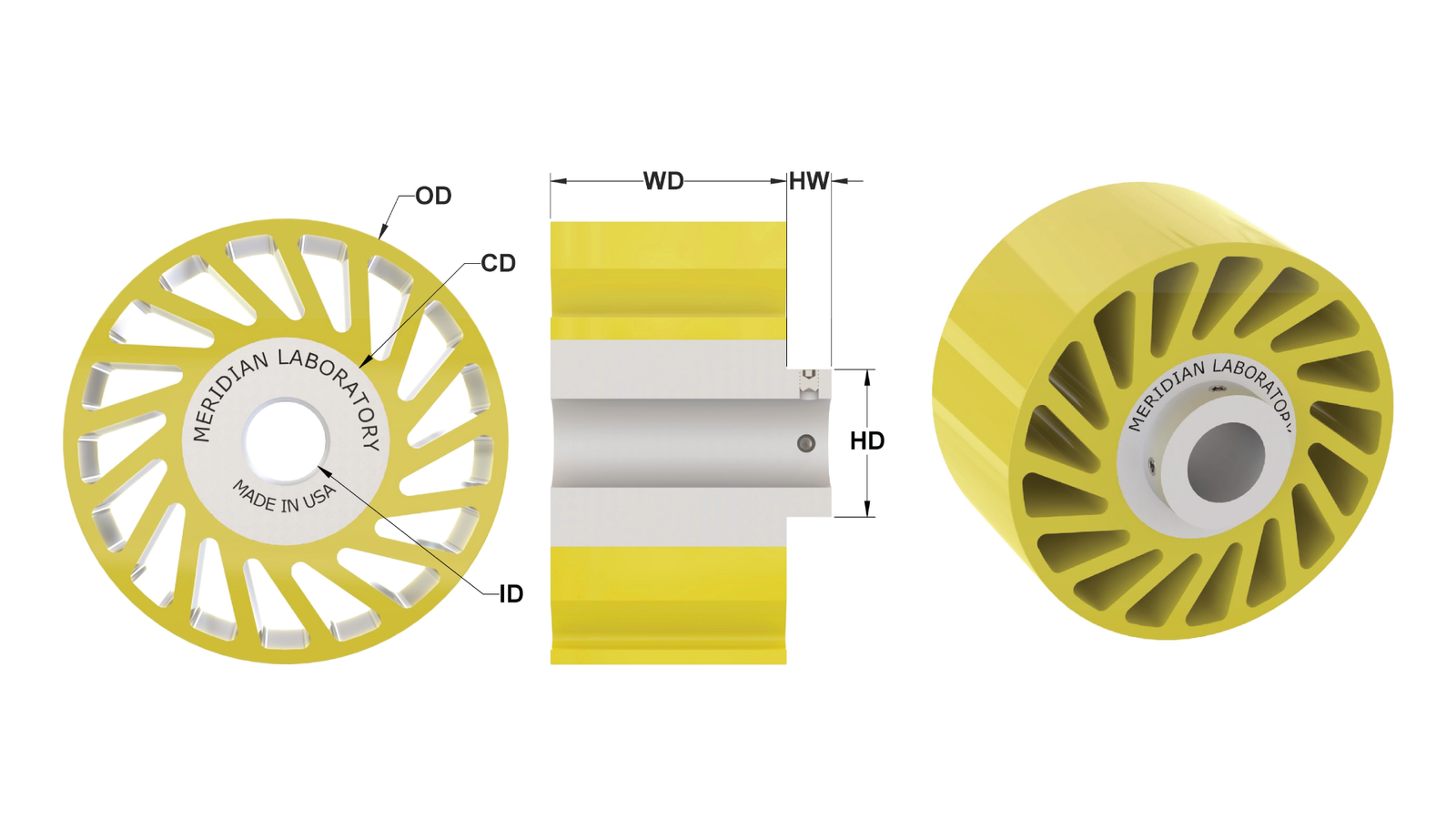

5.0″ Hubbed, No-Crush Drive Wheels are designed with an aluminum hub to lock onto a shaft with set screws (provided).

Have more questions about No-Crush Wheels? Visit our Frequently Asked Questions.

Photo may not be an exact representation of the product selected; for exact specifications see Datasheet Downloads.

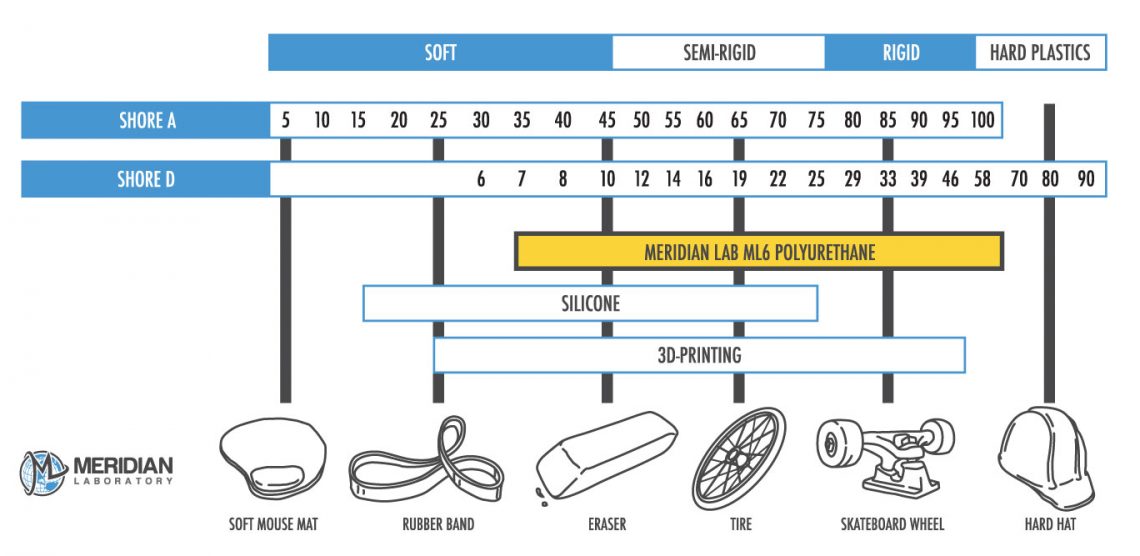

Durometer Scale (Click for More Information)

Durometer is the measurement of a material's hardness. For No-Crush Wheels, durometer is measured on the Shore A scale, where higher numbers indicate harder materials. The softest No-Crush Wheels are offered in 40 Shore A, while the hardest are available in 90 Shore A.

See the chart below for a comparison of Shore A durometer values to everyday objects.

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $65.00 |

| 11-20 | 5% | $61.75 |

| 21-49 | 10% | $58.50 |

| 50+ | 15% | $55.25 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Bulk Discounts

| Quantity | Discount | Per Item Price |

|---|---|---|

| 1-10 | 0% | $68.00 |

| 11-20 | 5% | $64.60 |

| 21-49 | 10% | $61.20 |

| 50+ | 15% | $57.80 |

Customization Options

Durometer

The durometer of a Zero Crush wheel can be specified with no effect on the price for any volumes required. For more information on durometer, check out our Technical Information and Frequently Asked Questions (FAQ) section below!

Color

For standard No-Crush Wheels, the color of the wheel is a designation to the durometer of the polyurethane (40A = Yellow, 55A = Blue, etc.), however, NoCrushWheels.com can provide specific durometers to your preferred colors at a slight upcharge, regardless of volume. For colors not shown or for an exact PMS / RGB color match, this can also be done but for an additional cost - Contact Us to find out more.

Mounting / Hub Type

The center hub (or core) of the No-Crush Wheels can be specified for your exact need. Customers can also provide their own cores (hubs, bushings, bearings, etc.) if this is preferred; otherwise, NoCrushWheels.com can deliver complete to exact specifications. Generally speaking, unless the bore sizing is something we already have available, it makes the most sense on quantities of 25 or more No-Crush Wheels.

Width

Modifying the surface width of a No-Crush Wheel is a simple request. This can be done in volumes as low as one piece. For significantly greater widths (2"+), we recommend stacking multiple Zero Crush Wheels together, as this will be the most cost and lead-time efficient manner.

Outside Diameter

All Zero Crush Wheels are molded exactly to size and dimension, using NoCrushWheels.com's time-proven techniques and methods to guarantee maximum quality. Molding No-Crush Wheels guarantees the exact same size and properties between wheels and batches - time and time again. To generate a custom outside diameter for a No-Crush Wheel involves producing tooling to this exact dimension and generally starts to make sense for estimated annual usage of 100+ No-Crush Wheels per year.

Spoke Profiles

Customers request custom spoke profiles for their No-Crush Wheels for many different reasons such as matching the exact profile of an existing wheel manufacturer that is no longer in business, wishing to keep the same durometer between all of their No-Crush Wheels but with different compliance properties, and sometimes simply because they have their mind set on something that is unique and specific to their No-Crush Wheels. Whatever the reason might be, NoCrushWheels.com can deliver custom spoke profiles, generally for orders where the estimated annual usage is 100+ No-Crush Wheels per year.

FDA Compliance

For applications which require FDA-Compliant polyurethane molded No-Crush Wheels, we offer special FDA-Compliant No-Crush Wheels (dry). This guarantees safe and compliant use of our Zero Crush Wheels for food, beverage, pharmaceutical, and other sensitive applications; this is available for volumes as low as 10 pieces.

Anti-Static

For applications which cannot create a static charge, NoCrushWheels.com offers special additives to its polyurethane anti-static No-Crush Wheels to minimize the amount of static potential and is available for order volumes as low as 10 pieces.

Build Your Custom No-Crush Wheel – In Under 1 Minute

Choose your size, durometer, and style. Get the perfect fit for your application – fast, simple, and precise.

Technical Information

WHEEL DEFLECTION CHARACTERISTICS

Wheel Deflection refers to the amount a No-Crush Wheel will compress or "crush". The amount of deflection depends on several factors, including the wheel’s diameter, width, and polyurethane durometer. Below, you will find deflection charts for our most common No-Crush Wheel sizes and durometers to help guide your selection.

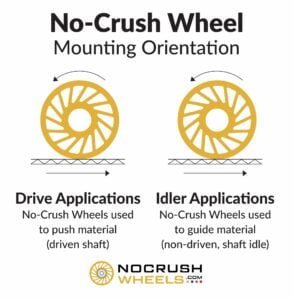

MOUNTING AND WHEEL ORIENTATION

Applications in which material is being driven/fed by a No-Crush Wheel are mounted opposite from applications in which the No-Crush Wheel is idling. Use this helpful diagram to determine the orientation of your No-Crush Wheel for best results!

APPLICATIONS & USES

Zero Crush Wheels can be used in so many different ways!

Here are just a few:

- Hold-Down Wheels for the corrugated cardboard and packaging industry

- Bottle Spacing Wheels to allow for bottles and other containers to pass by

- Labeling Wheels to provide pressure for labels to be applied to objects

- Flex-Grip Wheels to give maximum surface area onto objects being moved

- Metering Wheels to only allow objects to pass by at the proper time

Have another type of use for a No-Crush Wheel? Get in touch and let us know!

FREQUENTLY ASKED QUESTIONS

What is the right durometer of No-Crush Wheel for my application?

This is a very common question related to selecting a No-Crush Wheel, but perhaps the most challenging one to answer accurately!

Use the information below, in addition to our comprehensive No-Crush Wheel Deflection Charts to determine the best size and durometer of No-Crush Wheel for your application.

The durometer of a No-Crush Wheel can be generally correlated directly with how much compliance or "crush" the actual wheel will exhibit. A harder durometer or larger diameter No-Crush Wheel will exhibit less "give" or compliance than one with a lower durometer or smaller diameter; and while there is no SAE spec or any type of "standard" amount a No-Crush / Zero-Crush Wheel should exhibit, here are some common things to take into consideration when making a selection of No-Crush Wheel for your application:

- Force / Load: A heavy item, or one where a large amount of force is desired to hold down, or make contact with the No-Crush Wheel would require a higher durometer No-Crush Wheel. The lower the durometer, the less force will be required to "crush" the No-Crush Wheel.

- Rigidity of Item in Contact: For example in a labeling application, more delicate items such as corrugated cardboard boxes and paper products will be much less rigid than say a wine bottle passing by it. In both applications pressure is needed to apply a label, but a pre-made cardboard box will be much more susceptible to being crushed versus a wine bottle being broken, by the same durometer and size of No-Crush Wheel.

- Other Machine Adjustments: For applications where there is a large amount of variance between the materials coming in contact with a No-Crush Wheel, it is recommended that other areas allow for adjustment, beyond just relying on the "give" or compliance of a No-Crush Wheel. This can include hinged and spring loaded axles of rotation, machine screws or threaded rods, and other fixturing with adjustment opportunities.

Tech Tip: The most popular durometer of No-Crush Wheels is Shore A 40 durometer, also referred to as '40A'.

Generally speaking, it's best to choose a durometer of No-Crush Wheel to where the load/force exhibited onto the wheel does not completely "crush" the internal spokes of the wheels, as this will thereby max out the compliance of the No-Crush Wheel. The great part is that NoCrushWheels.com offers five durometers (40A, 55A, 70A, 80A, 90A) to meet all the needs you might have for your exact application.

What is Durometer? Why is it important?

Is it a device? A unit of measure? A scale?

Yes!

Durometer - du·rom·e·ter: an instrument for measuring hardness.

Technically speaking, a Durometer is a 'Duro-Meter' which is a device that is utilized to measure the hardness of something. However speaking more conventionally, Durometer is also used as a unit of measure for the hardness of softer materials. For No-Crush Wheels and other molded polyurethane rollers, idlers, and wheels, it is effectively how hard or soft the polyurethane which is bonded to the surface really is.

There are different scales which polyurethane and other rubber-like materials are measured under, including Shore A, Shore D, and Shore M, ranging from 0 to 100 points; the lower the number, the softer the hardness of the material on a given scale. Most conventionally molded polyurethanes typically lie in the Shore A and Shore D scales, with all of No-Crush Wheels residing in the Shore A scale. Below is a helpful chart to give you some real-world examples of what is comparable to the different hardnesses of Shore A and Shore D materials.

When selecting a No-Crush Wheel, it is important a Durometer is selected that adequately matches the use in which it is intended for. Too hard of a Durometer and the No-Crush Wheel will not "crush" or deform enough with regard to the material and force it is coming on contact with. Too soft of a Durometer and the No-Crush Wheel will "crush" and deform too much.

While there is no set SAE or universal compliance (crush) standard -- NoCrushWheels.com does have useful information to help get you started in the right direction.

The durometer of a No-Crush Wheel can be generally correlated directly with how much compliance or "crush" the actual wheel will exhibit. A harder durometer or larger diameter No-Crush Wheel will exhibit less "give" or compliance than one with a lower durometer or smaller diameter; and while there is no SAE spec or any type of "standard" amount a No-Crush / Zero-Crush Wheel should exhibit, here are some common things to take into consideration when making a selection of No-Crush Wheel for your application:

- Force / Load: A heavy item, or one where a large amount of force is desired to hold down, or make contact with the No-Crush Wheel would require a higher durometer No-Crush Wheel. The lower the durometer, the less force will be required to "crush" the No-Crush Wheel.

- Rigidity of Item in Contact: For example in a labeling application, more delicate items such as corrugated cardboard boxes and paper products will be much less rigid than say a wine bottle passing by it. In both applications pressure is needed to apply a label, but a pre-made cardboard box will be much more susceptible to being crushed versus a wine bottle being broken, by the same durometer and size of No-Crush Wheel.

- Other Machine Adjustments: For applications where there is a large amount of variance between the materials coming in contact with a No-Crush Wheel, it is recommended that other areas allow for adjustment, beyond just relying on the "give" or compliance of a No-Crush Wheel. This can include hinged and spring loaded axles of rotation, machine screws or threaded rods, and other fixturing with adjustment opportunities.

Tech Tip: The most popular durometer of No-Crush Wheels is Shore A 40 durometer, also referred to as '40A'.

Generally speaking, it's best to choose a durometer of No-Crush Wheel to where the load/force exhibited onto the wheel does not completely "crush" the internal spokes of the wheels, as this will thereby max out the compliance of the No-Crush Wheel. The great part is that NoCrushWheels.com offers five durometers (40A, 55A, 70A, 80A, 90A) to meet all the needs you might have for your exact application.

Which direction should I mount my No-Crush Wheel?

This is a commonly asked question about No-Crush Wheels and one that generally depends on what the No-Crush Wheel is being used for in the application.

Applications in which material is being driven/fed by a No-Crush Wheel are mounted opposite from applications in which the No-Crush Wheel is idling. Use this helpful diagram to best determine the orientation of your No-Crush Wheel for best results!

It should be noted that all applications are typically unique to their own degree, but on a general whole these guidelines can help you decide which direction / orientation is best for your No-Crush Wheel.

Still have questions? Be sure to Contact Us - our team is more than happy to help answer this, and any other questions you might have!

I need a LOT of No-Crush wheels...are there volume discounts?

Absolutely!

While NoCrushWheels.com was created as your single source for high-quality, American-Made, polyurethane No-Crush Wheels in volumes as low as one piece...we equally support high volume original equipment manufacturers (OEM), and maintenance/repair operations too!

The online store at NoCrushWheels.com is set up to be a quick way to find, spec, and purchase No-Crush Wheels! For larger volumes, NoCrushWheels.com accepts blanket purchase order agreements, and can offer discounted pricing and scheduled deliveries to meet your needs for higher volumes. Get in touch with us to get started!

What are the tolerances of your No-Crush Wheels?

Generally speaking the most important tolerance aspect of a No-Crush Wheel is the tolerance of the inner core (bore diameter) of the hub, bearing, or surface that mates with whatever is running through the center.

All of the internal cores utilized by NoCrushWheels.com are precision CNC machined and have a tight bore tolerance to ensure maximum concentricity. Generally speaking all cores have a bore tolerance of +0.002" / -0.000" to accurately slide over and affix to common shaft sizes.

The outside diameter of our Zero Crush Wheels are precision molded to the same diameter each and every time, ensuring you get the same performance on every wheel. There is no grinding or post-finishing that occurs to the outside diameter, ensuring a smooth and consistent surface is maintained that does not collect debris over time. Because of the nature and design of no crush wheels however, flex in the actual wheels will happen (by design) and therefore a true total indicated runout measurement is impossible to measure and provide a tolerance for.

The width of our standard Zero Crush Wheels is generally +/- 0.075". For more detailed datasheets, please click here.

If you have questions or require custom or tighter tolerances, please feel free to contact us!

How long will a No-Crush Wheel last?

NoCrushWheels.com only manufactures the highest quality of Zero Crush Wheels in the United States of America. Having end-to-end and full control of all facets of production, from our exclusive industrial ML6 polyurethane base polymers, to strict process control procedures on the production floor guarantees that we produce high quality No-Crush Wheels consistently, each and every time.

Nevertheless, estimating how long a No-Crush Wheel will last in your application is still a challenge due to the wide range of applications and use cases, and subsequent variables that exist. Generally speaking, the polyurethane durometer, application force / pressure (load), speed, environmental factors, and rotations (cycles) will influence how long a No-Crush Wheel will last in an application.

Generally, the higher the durometer, the less deformation a No-Crush Wheel will have, and it will exhibit less deflection as pressure is being placed on it. The less cyclic deflection a No-Crush Wheel exhibits, decreases the stress that the grain structure sees and the wheel will be less prone to eventual cracking. The tradeoff comes with having less "give", and the wheel might not be flexible enough for your application or load being placed on it.

In summary, similar to an automotive tire - "results may vary" based on a multitude of factors and there is no set lifetime a No-Crush Wheel can or should last. On a whole, we hear many success stories and have a growing list of repeat customers that have NoCrushWheels.com as their single-source supplier of polyurethane No-Crush Wheels for all their applications.

The team at NoCrushWheels.com is happy to provide guidance as to what might work best for your application. While no two applications are the same, the quality of product and service is something you can always count on being the same each and every time.

How is Polyurethane ML6® different from other polyurethanes?

NoCrushWheels.com produces only the highest quality of polyurethane No-Crush Wheels without compromise. Much of this stems from the rich history of its parent company, Meridian Laboratory and its long tenure in producing the highest quality of molded polyurethane solutions since 1963.

Polyurethane comes in many different forms, quality grades, and ingredients. NoCrushWheels.com utilizes its own unique and proprietary blends of polyurethane, trademarked 'Polyurethane ML6®' by Meridian Laboratory. Polyurethane ML6® is uniquely configured for industrial applications to provide the best quality and longevity, while guaranteeing the best tolerances available within the industry.

For more information on what sets Polyurethane ML6 apart from the rest - click here!

How long has NoCrushWheels.com been around?

NoCrushWheels.com was founded based on consistently hearing customers say – “we always have a need for these types of No-Crush wheels…we just never know where to find them!” As they say, build it and they will come - NoCrushWheels.com was officially launched in 2023 to be your source of high-quality, molded polyurethane Zero Crush wheels.

While the NoCrushWheels.com brand and website are still relatively new, the company behind NoCrushWheels.com is far from inexperienced! NoCrushWheels.com's parent company, Meridian Laboratory has been a manufacturer of high-quality molded polyurethane products since 1963. Meridian Laboratory / NoCrushWheels.com is located outside of Madison, WI and has the ability to deliver high-quality, standard, and custom molded polyurethane rollers, wheels, grippers, and more. Meridian Laboratory’s ML6 Polyurethane is a superior blend of polyurethane that is unique and exclusive to Meridian Laboratory. This ensures the most durable, long-lasting, and high-quality polyurethane overmolded and molded polyurethane products are provided to customers worldwide.

You can trust the decades of experience that the Meridian Laboratory team has to provide the highest quality molded polyurethane No-Crush Wheels for your application! Have a need for other molded polyurethane rollers and products? Meridian Laboratory’s Polyurethane ML6 division has the ability to deliver molded polyurethane rollers, wheels, bearings, cam followers/track rollers, idler wheels, grippers, and more!

Check out Meridian Laboratory now to learn more!

Do you offer other custom sizes or options for No-Crush Wheels?

Absolutely!

NoCrushWheels.com is your single-source provider of No-Crush Wheels! Being the manufacturer, we have complete control of the complete product from concept to reality and welcome new types and sizes of No-Crush Wheels. Whether you are looking for a hub style, bore size, wheel diameter, or custom profile of polyurethane Zero-Crush Wheel we have the ability to deliver custom No-Crush Wheels in a cost and time efficient manner.

Check out our Custom No-Crush Wheels page to configure your perfect No-Crush Wheel!

Some helpful information relative to customization options for No-Crush Wheels can be found below:

Durometer: The durometer of a Zero Crush wheel can be specified with no effect on the price for any volumes required. For more information on durometer, check out our Technical Information and Frequently Asked Questions (FAQ) section below!

Color: For standard No-Crush Wheels, the color of the wheel is a designation to the durometer of the polyurethane (40A = Yellow, 55A = Blue, etc.), however, NoCrushWheels.com can provide specific durometers to your preferred colors at a slight upcharge, regardless of volume. For colors not shown or for an exact PMS / RGB color match, this can also be done but for an additional cost - Contact Us to find out more.

Mounting / Hub Type: The center hub (or core) of the No-Crush Wheels can be specified for your exact need. Customers can also provide their own cores (hubs, bushings, bearings, etc.) if this is preferred; otherwise, NoCrushWheels.com can deliver complete to exact specifications. Generally speaking, unless the bore sizing is something we already have available, it makes the most sense on quantities of 25 or more No-Crush Wheels.

Hub Material: No-Crush Wheels offered by NoCrushWheels.com have incredible bond strength to the cores which they are molded to - this is actually one of the many features that sets our quality and performance apart from the imitators! Zero Crush Wheels can be manufactured with different core materials, including aluminum, stainless steel, brass, bronze, and even plastics such as PEEK, Delrin, and other non-metallic materials. This generally makes the most sense in quantities of 25 or more No-Crush Wheels.

Width: Modifying the surface width of a No-Crush Wheel is a simple request. This can be done in volumes as low as one piece. For significantly greater widths (2"+), we recommend stacking multiple Zero Crush Wheels together, as this will be the most cost and lead-time efficient manner.

Outside Diameter: All Zero Crush Wheels are molded exactly to size and dimension, using NoCrushWheels.com's time-proven techniques and methods to guarantee maximum quality. Molding No-Crush Wheels guarantees the exact same size and properties between wheels and batches - time and time again. To generate a custom outside diameter for a No-Crush Wheel involves producing tooling to this exact dimension and generally starts to make sense for estimated annual usage of 100+ No-Crush Wheels per year.

Spoke Profiles: Customers request custom spoke profiles for their No-Crush Wheels for many different reasons such as matching the exact profile of an existing wheel manufacturer that is no longer in business, wishing to keep the same durometer between all of their No-Crush Wheels but with different compliance properties, and sometimes simply because they have their mind set on something that is unique and specific to their No-Crush Wheels. Whatever the reason might be, NoCrushWheels.com can deliver custom spoke profiles, generally for orders where the estimated annual usage is 100+ No-Crush Wheels per year.

FDA Compliance: For applications which require FDA-Compliant polyurethane molded No-Crush Wheels, we offer special FDA-Compliant No-Crush Wheels (dry). This guarantees safe and compliant use of our Zero Crush Wheels for food, beverage, pharmaceutical, and other sensitive applications; this is available for volumes as low as 10 pieces.

Anti-Static: For applications which cannot create a static charge, NoCrushWheels.com offers special additives to its polyurethane anti-static No-Crush Wheels to minimize the amount of static potential and is available for order volumes as low as 10 pieces.

If you have other styles or needs in mind, we are your single-source for standard and custom No-Crush Wheels. Contact Us today to get started!

Why are there so many names for these wheels?

This is a question we even ask ourselves at NoCrushWheels.com sometimes, and to top it off we are certain we haven't even heard them all yet!

Whether at tradeshows, during phone calls, or in-person visits - we hear these types of spoked wheels get called all kinds of different things. About the only thing consistent about their inconsistent naming convention is that the names typically have less to do with their shape, and more about where they are used and what they do.

Some, but likely not all of the names these types of wheels get called include:

- No-Crush Wheels

- Zero-Crush Wheels

- Flex Grip Wheels

- Durasoft Wheels

- Pacing Wheels

- Metering Wheels

- Bottle Spacing Wheels

- Hold-Down Wheels

- Spider Wheels

No-Crush Wheels are incredibly versatile in how they can be used in applications, and below are just a few examples of how they are used and potentially some insight on where this growing list of names may have stemmed from.

No-Crush, Zero-Crush Wheels, and Flex Grip imply that whatever object they are coming in contact with presumably do not get damaged or crushed in the process of passing by the wheels - all the while applying grip or pressure. For example, corrugated cardboard boxes passing by a wheel which applies pressure to a label applicator needs give to account for variability in box dimensions on a production run. A No-Crush / Zero-Crush Wheel will have "give" in it, and subsequently avoid crushing or damaging the corrugated cardboard box.

Pacing, Metering, and Bottle Spacing Wheels generally implies something that is held back by the wheel until the appropriate time where the wheel is indexed to then allow for the product to pass along to the next step in the process. For example, picture a series of wine bottles on a linear conveyor line that get labeled by an applicator machine. The group of glass bottles will stack up and the Pacing / Metering / Bottle Spacing Wheel indexes to allow individual wine bottles to pass on and get labeled before moving on to the next stage of the process.

Hold-Down Wheels imply that some type of product is being held down onto a base layer, or potentially "joined" to another material but it needs "give" to allow for variance in material thickness. An example of this would be two layers of adhesive backed papers that package a product in a void in the center. Obviously pressure needs to be applied to the materials passing by, while allowing for "give" when the actual product being packaged (sandwiched) passes.

As for Spider Wheels -- well, that's anyone guess and the closest thing we have been able to deduce is from the shape of the wheels themselves, but if you have other thoughts, by all means Contact Us -- we would love to hear even more names for these interesting wheels!

What is the typical lead time?

A typical lead time for standard No-Crush Wheels for a low volume order (<10 pieces) is typically around two weeks. Since we have so many variations and sizes, it is difficult to keep them all in stock at all times. For custom No-Crush Wheels, lead times can vary from 2-6 weeks typically, depending on the complexity of the customized wheels.

Feel free to Contact Us at any time should you have any questions - we are happy to help!

How strong is the bond between the No-Crush Wheel and the core?

NoCrushWheels.com relies on the engineering expertise and manufacturing excellence of its parent company, Meridian Laboratory, Inc. who has been a manufacturer of standard and custom molded polyurethane drive wheels, polyurethane idler wheels, polyurethane coated cam followers, polyurethane coated bearings, robotic gripper fingers, and more since 1963.

Aside from the many things which set Meridian Laboratory and NoCrushWheels.com apart from the competition, bond strength of the polyurethane to the core material itself is one of the things which we are best known for. Taking the time to properly prep the surfaces, and using tightly controlled processing techniques during the polyurethane molding process guarantees an excellent bond between the polyurethane and the core material.

Oftentimes customers approach us stating how over time and use their rollers and wheels become delaminated from the core, ultimately rendering them useless. With our proven techniques and expertise you can be guaranteed a No-Crush Wheel that outperforms and outlasts, ultimately providing you less downtime, more savings, and the best return on investment.

Are there any differences between the colors?

No - the default colors assigned to the durometers is a simple way to keep track of the different durometers (hardness) of No-Crush Wheels.

NoCrushWheels.com can mix and match colors and durometers as well to best fit your performance and color requirements! Finally, if you are looking for a color not listed - reach out and get in touch today to learn how we can create No-Crush Wheels to your exact needs!

Does polyurethane leave behind any residue or mark my product in any way?

No!

ML6 Polyurethane is an incredible material, formulated by and exclusive to NoCrushWheels.com and is ideal for use in manufacturing, production, laboratory, and other industrially oriented applications. Molded ML6 polyurethane by NoCrushWheels.com will not leave behind any type of color, residue, or marking on the products it comes in contact with.

Do you offer any FDA compliant no-crush wheels?

Yes!

NoCrushWheels.com offers custom styles, sizes, and FDA compliant versions of its No-Crush Wheels. FDA Compliant polyurethane No-Crush Wheels are an option that can be best specified through contacting us here for more information!

How do you clean a No-Crush Wheel?

Cleaning a polyurethane No-Crush Wheel is simple. The molded polyurethane finish guarantees a closed-cell surface (versus a ground finish) and therefore doesn't trap contaminants from the air, or from the products the No-Crush Wheels come in contact with. This is particularly important for No-Crush Wheel applications which come in contact with materials that have a tendency to leave behind substrates or flake.

Using any type of white solvents (alcohol, ketone, Methyl-Ethyl-Ketone, etc.) you can wipe the wheels clean and restore the smooth, molded polyurethane surface of the No-Crush Wheel.

Can you match the size and / or profile of an existing No-Crush Wheel I have?

Absolutely!

NoCrushWheels.com has the ability to match the profile and sizes of any existing No-Crush Wheels you might have, quick and cost effectively. If you have a drawing or sample Zero Crush Wheel of what you are attempting to source - check out our Custom No-Crush Wheel configurator to send us a request for a quotation!