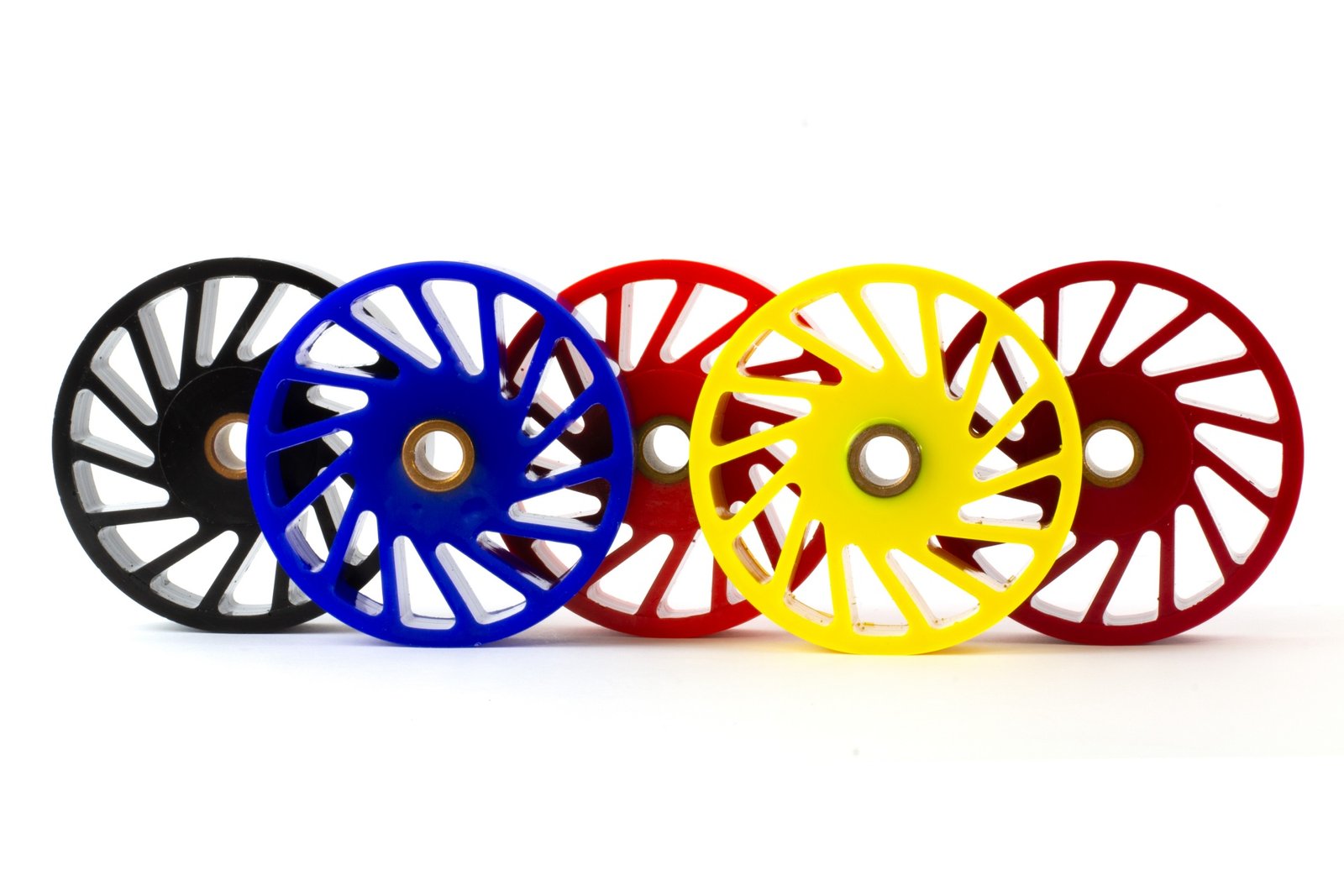

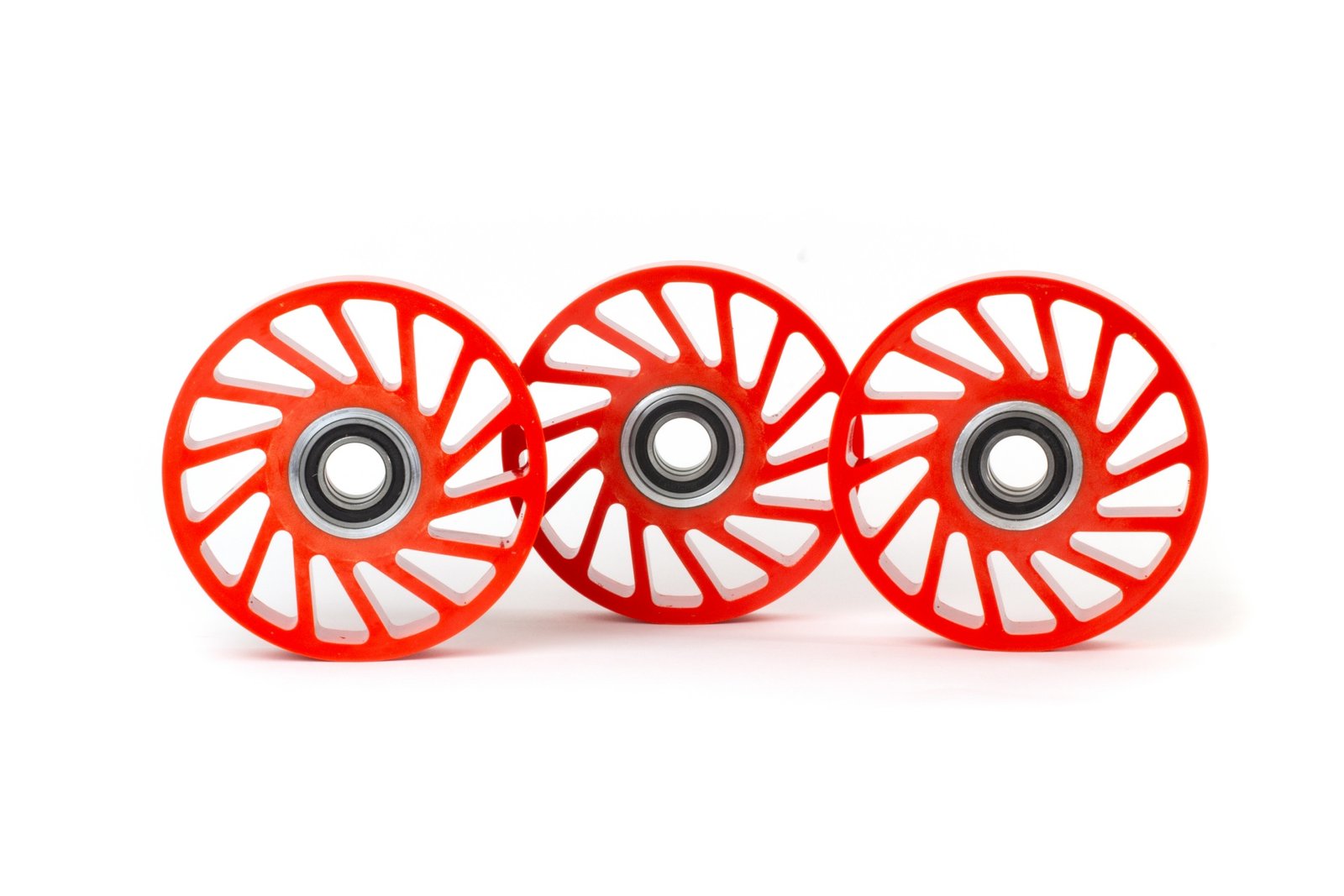

Check out our new custom No-Crush Wheel Configurator. Designed for engineers, machine builders, designers, and OEMs, this tool allows for the quick and simple configuration of custom-made No-Crush Wheels that are tailored to your specific application requirements.

Customization at Your Fingertips

Our configurator offers a variety of customization options, ensuring your No-Crush Wheels are precisely made to what your machinery needs:

- Select Your Style: Select the type of your custom No-Crush Wheel, including hubbed, idler, bearing, coreless, keyway, and other styles based on the function of your custom No-Crush Wheel. Choose from a variety of Zero-Crush Wheel types to match your application

- Custom Dimensions: Customize the outside diameter, width, and inside diameter to meet your exact application needs

- Durometer: Specify the durometer of your No-Crush Wheel to have the perfect amount of pressure onto a material or object

- Special Additives: Customize your Zero-Crush Wheel with options like anti-static for sensitive material or an FDA-compliant additive for food processing applications

Designed for Diverse Industries

The versatility of our Custom No-Crush Wheels makes them ideal for a wide array of industries and applications. Here’s a glimpse of where they can make a difference:

- Packaging and Printing: Ensure gentle handling of sensitive materials and finished products

- Food and Beverage: Utilize FDA-compliant No-Crush wheels for safe and hygienic processing

- Manufacturing: Improve product flow and reduce downtime with durable, application-specific Zero-Crush wheels

- Automation and Robotics: Enhance precision and efficiency with custom-configured No-Crush wheels

Why Choose NoCrushWheels.com?

Choosing our custom configurator means more than just getting a No-Crush Wheel that fits. It means:

- Unbeatable Quality: Each No-Crush Wheel is delivered with exceptional quality, including molded tolerances down to 0.001”.

- Exclusive Polyurethane Blend: ML6 polyurethane is made of high quality raw materials, designed to meet the needs of industrial, scientific, and high performance applications.

- Precision Manufacturing: Our polyurethane molding process achieves the final part dimensions without grinding, retaining the beneficial outer layer or “skin” of the polyurethane, ensuring optimal friction and longevity.

- Performance: For most applications, polyurethane outperforms rubber, silicone, nitrile, and many other materials and is durable against wear and chemical exposure.

- Support: Our expert team is always ready to assist, ensuring you get the most out of your custom No-Crush Wheels.

Get Started Today

NoCrushWheels.com is proud to offer a solution that easily allows you to customize No-Crush Wheels. Our custom No-Crush Wheel configurator is a great tool to enhance your performance and reliability in any application. Check out our custom Zero-Crush Wheel configurator to create the perfect wheel for your application!